The Hydrogen Energy and Ammonia Application Research Center team at the Energy Research Institute of Hefei Comprehensive National Science Center has achieved a notable distinction with their research paper being selected as the cover article in the prestigious journal "Engineering". The study, titled "Experimental Study on Ammonia Co-Firing with Coal for Carbon Reduction in the Boiler of a 300-MW Coal-Fired Power Station," was published in the journal's Volume 40, Issue 9.

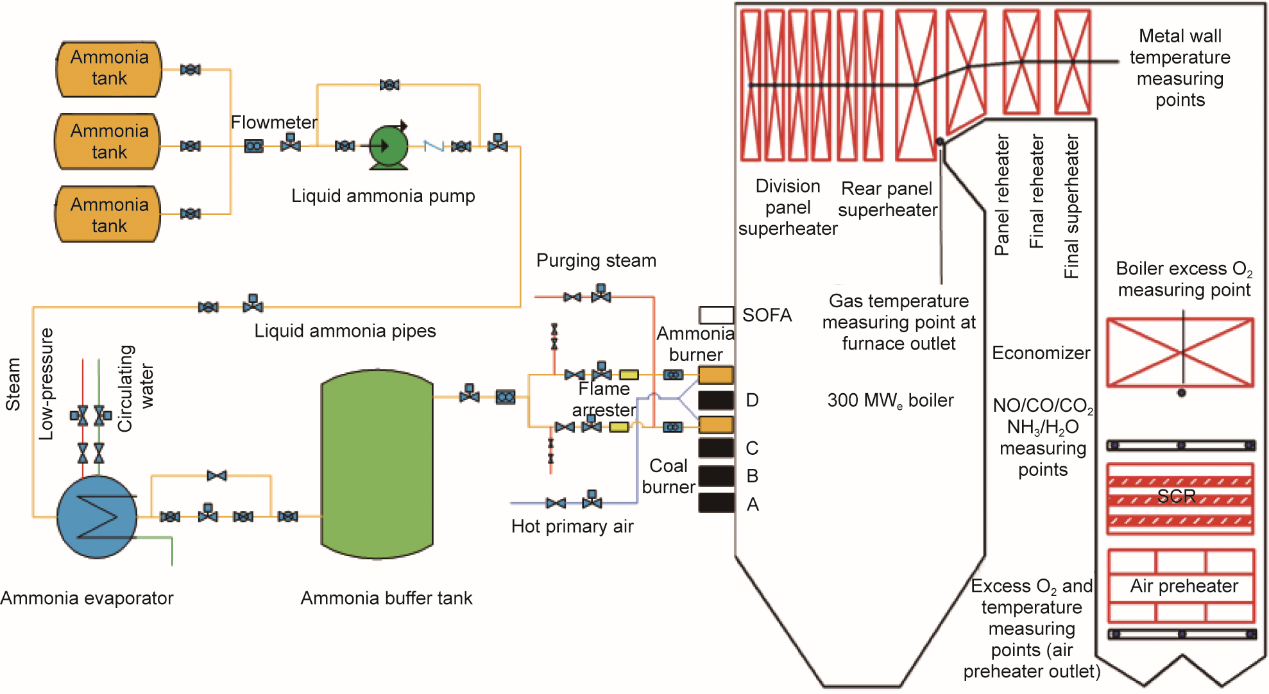

This groundbreaking research explores the technical feasibility of ammonia co-firing in coal power plants as a means to reduce carbon emissions. The team conducted a pioneering experiment by retrofitting a 300-MW coal-fired power station boiler with two tiers of eight pure-ammonia burners, enabling co-firing at a heat ratio mixture of 20% to 10%, corresponding to a load range of 180 MW to 300 MW. This was the first trial of its kind worldwide.

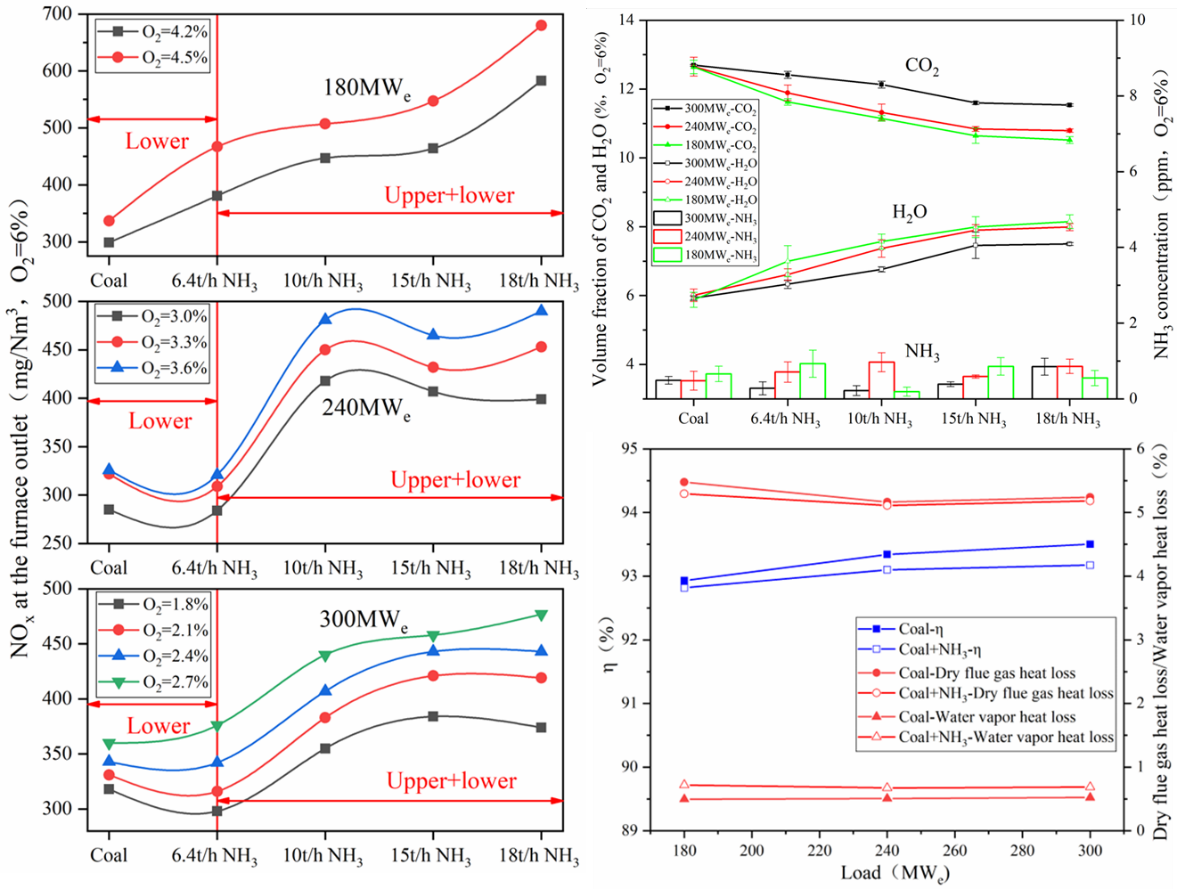

The study investigated the effects of various operational parameters, such as oxygen levels, ammonia injection points, unit loads, and co-firing ratios, on NOx emissions and ammonia burnout. It also examined the impact on boiler heat transfer and thermal efficiency. Key findings include:

- NOx emissions in the exhaust gas are adjustable and controllable. The presence of ammonia in the co-firing process makes NOx emissions more sensitive to changes in boiler oxygen levels. During rich combustion, the high-temperature reduction inside the furnace results in NOx levels that are even lower than those achieved with coal alone.

- At the furnace outlet, ammonia concentrations remained below 1 ppm, indicating complete combustion of ammonia.

- The impact of ammonia co-firing on boiler thermal efficiency is minimal. The slight increase in sensible heat loss of water vapor and solid unburned loss in flue gas after ammonia injection resulted in a marginal decrease in boiler thermal efficiency (ranging from 0.12% to 0.38%). However, the boiler heating surface can meet the heat exchange demand without the need for modification under the conditions of this experiment.

The research has been supported by several funding sources, including the national key research and development plan, collaborative projects with the Chinese Academy of Engineering and local governments, the National Natural Science Foundation of China, the Anhui Provincial Natural Science Foundation, the collaborative innovation project of Anhui universities, and the Energy Research Institute of Hefei Comprehensive National Science Center's (Anhui Energy Laboratory) independent initiative. The paper also lists co-authors from Ammonia Technology Co., Ltd. and the Institute of Plasma Physics, Hefei Institutes of Physical Science, Chinese Academy of Sciences.

The research team is committed to further exploring the effects of ammonia-coal co-firing at higher ratios and unit loads on boiler performance, with the goal of advancing the carbon reduction potential of ammonia co-firing in coal-fired power units.

For more details, please see the full paper at:

http://www.engineering.org.cn/en/10.1016/j.eng.2024.06.003

Figure 1. Schematic diagram of ammonia co-firing system for a 300 MW coal-fired power station boiler

Figure 2. Influence of boiler operating oxygen level, ammonia blending amount, and unit load on exhaust gas NOx, ammonia, and boiler efficiency